दहॠà¤à¤¾ पà¥à¤§à¤¾

Price 1500000 आईएनआर/ टुकड़ा

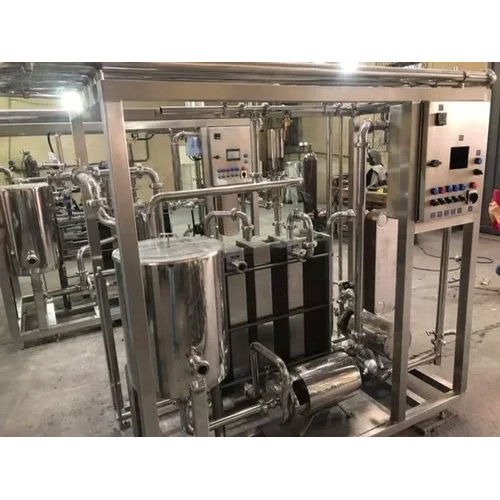

दहॠà¤à¤¾ पà¥à¤§à¤¾ Specification

- प्रॉडक्ट टाइप

- दही का पौधा

- सामान्य उपयोग

- दूध, पनीर, दही, दही

- मटेरियल

- स्टेनलेस स्टील

- टाइप करें

- ,

- कम्प्यूटरीकृत

- नहीं

- ऑटोमेटिक

- हाँ

- रंग

- चाँदी

- वारंटी

- 1 वर्ष

दहॠà¤à¤¾ पà¥à¤§à¤¾ Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- 10 प्रति महीने

- डिलीवरी का समय

- 7 दिन

About दहॠà¤à¤¾ पà¥à¤§à¤¾

| Country of Origin | Made in India |

| Capacity | 500 litres/hr,1000 litres/hr,2500 litres/hr,Required Capacity |

| Equipment Type | Milk Pasteurizer |

| Application | CURD,Milk,Yogurt,Cheese |

| Automatic Grade | Automatic,Semi-Automatic,Manual |

| Milk Processing Capacity | 5000 LPH |

Being the leading names in industry we are involved in offering to our esteemed clients an exclusive range of Curd Plant.

These are easy to operate and are available in different specifications. These are provided with latest pieces of equipment to meet the variegated preferences of our clients.

High-Performance Automatic Dairy Production

This Curd Plant is engineered for seamless and continuous production, offering the automation needed to meet growing dairy demands. With features designed for simplicity and efficiency, it significantly increases productivity while reducing manual intervention. Suitable for producing milk, cheese, curd, and yogurt, it ensures versatility for modern dairy operations in India.

Durable Stainless Steel Construction

Manufactured from food-grade stainless steel, the plant guarantees superior hygiene and long-term durability even under rigorous use. Its corrosion resistance and easy-to-clean surfaces make it perfect for dairy processing, helping maintain stringent quality standards throughout the production cycle.

FAQs of Curd Plant:

Q: How does the Curd Plant operate without computerized controls?

A: The Curd Plant utilizes a mechanical automatic system that relies on robust, well-engineered components for all operations. Its processes, such as mixing, fermentation, and curd formation, are managed without the need for computerized controls, making the plant easier to maintain and operate.Q: What types of dairy products can be processed using this Curd Plant?

A: This plant is designed to process milk, cheese, curd, and yogurt. Its versatile design allows for the seamless production of these popular dairy items, making it a valuable asset for manufacturers and suppliers seeking multi-product capability.Q: When should routine maintenance be performed on this dairy processing plant?

A: To ensure optimal performance and longevity, it is recommended to conduct routine maintenance at regular intervalstypically every three to six months. This includes inspecting and cleaning stainless steel surfaces and checking all moving parts for wear.Q: Where is this Curd Plant manufactured and exported from?

A: The plant is manufactured, supplied, and exported from India, supported by a network of experienced professionals specializing in dairy processing machinery. It is designed to meet both domestic and international standards.Q: What is the process for producing curd in this plant?

A: The production process involves heating milk, adding a starter culture, and allowing controlled fermentation in the plants dedicated chambers. The automatic system ensures consistent temperature and timing, resulting in uniform, high-quality curd every batch.Q: How can dairy businesses benefit from using this automated Curd Plant?

A: Businesses benefit from increased production efficiency, consistent product quality, and minimal manual labor requirements. The stainless steel construction ensures hygiene and easy cleaning, while the plants automation accommodates large-scale operations.Q: Is training or technical support available for installation or maintenance?

A: As a manufacturer, exporter, and supplier, we offer guidance during installation and provide after-sales support to ensure smooth operation and maintenance of the plant, helping businesses integrate the system seamlessly into their workflow.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in डेयरी उपकरण Category

रोटरी कप भरने की मशीन

मूल्य की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

माप की इकाई : टुकड़ा/टुकड़े

वारंटी : 1 वर्ष

मूल्य या मूल्य सीमा : आईएनआर

मटेरियल : स्टेनलेस स्टील

घी के मवेशी

मूल्य की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

माप की इकाई : टुकड़ा/टुकड़े

वारंटी : 1 वर्ष

मूल्य या मूल्य सीमा : आईएनआर

मटेरियल : स्टेनलेस स्टील

बल्क मिल्क कूलर

मूल्य की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

माप की इकाई : टुकड़ा/टुकड़े

वारंटी : 1 Year

मूल्य या मूल्य सीमा : आईएनआर

दही का पौधा

मूल्य की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

माप की इकाई : टुकड़ा/टुकड़े

वारंटी : 1 वर्ष

मूल्य या मूल्य सीमा : आईएनआर

मटेरियल : स्टेनलेस स्टील

|

SHREYA ENGINEERING WORKS

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें